M3D Micro

Printer: M3D Micro

Connection: Tethered (only option) to a MacBook Air

Filament: Foxsmart PLA, Opaque red

This printer was borrowed from a friend (who has been trying to sell it for... about a year now) in a fit of desperation. With my Mini fried and orders waiting for me to print and 2 day shipping still being hellishly slow in the face of anxiety, it was worth a try to see if I could get something that worked...

Set up:

The M3D Micro I received was a 2nd hand unit, so I can't comment on the packaging or included materials. First thing I did was download and install the software from the official site. Then install the mono framework. Then reboot so that the laptop and printer would acknowledge the other's existence. Once the two were talking, I had the Micro unload the proprietary filament and began researching what I needed to do to use my own. 20 seconds of a YouTube tutorial later and the easy solution was found: The top of the hot end has a small hole you can just stick whatever filament you'd like into. Considering that the filament holder *under* the bed, while keeping the profile slim and minimalistic, is terribly impractical.

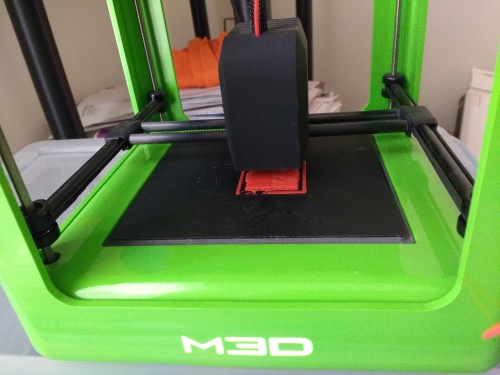

Loading and unloading filament is a bit of a chore in a "are we there yet" sort of way. The machine takes care of most of the work, but it takes about 3 minutes getting to temperature, pushing out a "small" amount of filament [see photo] and then retracting. If you've top loaded, it tells you to pull up. If you've loaded it under the bed... you can't do much of anything because the hot end is in the way. Or rather, you can awkwardly move around it, jimmy up the print bed, wiggle the spool out with the inch or so clearance the hovering hot end has given you, and pull it out that way. (Don't load the filament under the print bed. Just don't.) Noise wise, after ejecting the filament there continued to be a high pitched "cheap CFL" whine that continued until I unplugged the thing. (Telling the hot end to stop heating did nothing so not really sure what was causing it.)

Loading up, I used the code off the proprietary spool to tell the program I was using PLA, and it seemed happy enough to just pull that in through the hole in its head. Filament loaded, I went to open a .stl to get going, only to be met with a repeated error. "There was an error loading the file." Every .stl resulted in this error and google was no help, giving only the bain of every tech support search: A thread with the exact error and only one utterly unhelpful reply.

1 hour, 3 installs and futzing later, a work around was installed so I could use 3rd party software to control the machine. Attempting configure the Slic3r to know what I was working with, however, resulted in utter crap prints. Suspecting that the specs listed were a lie, I gave it a break for the night.

The next morning an email from tech support had arrived: "Try dragging and dropping the stl file directly into the software," it advised. And lo and behold, somehow, it worked where following the logical path of using the "open model" button had failed.

Strange, but hey, I was finally set up and ready to print! .... 16 hours after getting the unit, but victory is still a victory right? Of course right Moving on...

Printing:

To say that the Micro printer is frustratingly slow feels like it's an understatement. The time it takes to heat up is nice and swift, however, it takes the printer a good 5 minutes from when when you hit "print" to actually get to that point. When it starts up, it also does the functional equivalent of flinging itself against the wall in slow motion, the print head moving to the ends of the bed and trying to go beyond them for a good 15 seconds before testing the other direction similarly. So far it seems harmless, but it was a bit concerning the first time.

When it's actually printing, the Micro is fairly quiet. There are small scronks and twees of the motor moving the head around, and the wrrr of the fan and the high pitched "your tv is on and has no picture" whine of the hotend getting heat. The motor sounds are, however, punctuated like a stereotypical Shatner impersonation (or, for those of us who remember, jokes about 300 baud modems.) There is a very noticeable pause between lines of gcode. A function of being tethered by USB vs reading from a memory card, perhaps? Or just of a very slow moving process. Either way, it easily triples or quadruples the length of a complex print.

The software is minimalistic on information. It'll tell you what the printers doing that moment, the % of the model printed, and an estimate of time left to go. When it finishes, the status window simply vanishes, leaving you back at the screen you started the print from, with no end report of time taken or anything, which was a bit disappointing. The mono framework (which runs concurrently with the m3d software) will also tell you the current temperature of the hot end and percentage printed, and if you click the "log to screen" option, will record stop and end times.

The Prints:

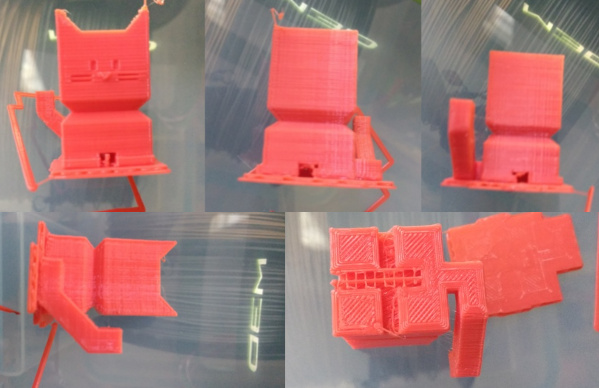

Cali Cat (http://www.thingiverse.com/thing:1545913)

The thingiverse information for Cali Cat says it prints in under an hour. On Medium/Medium settings, with a brim, it took a smidge over 2 hours to print. Taking measurements, the cat was not exactly to scale. Height was 34.25mm, vs 35mm, Width, 20.1mm vs 20mm, Depth, 19.8mm vs 20mm.

A quick search found that this is a common problem with this printer, one post mentioning: "I contacted tech support and they said a 2% error was in spec."

Visibly, the quality isn't that bad. There's mild stringing and bumps from the tail to the body, more noticeable bumps on the front edges of the ears.

Spinner Ring Band

Spinner rings are the thing I print the most of, being the bread and butter of my business. I loaded up one of my standard models, a file that on the MP Mini, took roughly 10-15 min to print. The micro took 45 minutes and... delivered a rather sub par result.

I'm not entirely sure what it was attempting to do with the print and without a preview of the gcode, it's hard to do anything but just guess. It looks like it may have tried to add supports... for part of the ring. Other parts of the ring look like it either the filament just didn't adhere.

Considering this a failure, I started a 2nd print, this time using a raft. At 52 minutes, the raft added 7 minutes to the print time and did indeed firm up the bottom. Looking at the underside of the draft added to the theory that the messy bottom of the first print was some misguided attempt at supports.

The detail, however, still left a lot to be desired. Excessive stringing still plagued the center, and some of the design just seemed to give up partway through.

Overall:

Very swiftly in this experiment I gave the Micro the nickname "PoS" which, while unkind, is indicative of the level of frustration. Considering this printer is supposed to be a plug and play/load and go/press a button and print printer, I can very easily understand why the person I got it from gave up so swiftly on trying to figure it out.

Fran Indexes (on a scale of 1-5, 1 being low, 5 being high)

Frustration level: 3

Satisfaction level: 2.

Quality of day 1 prints: 2 (Bleh)

Quiet Quotient : 4 (Pretty quiet)

Recommended knowledge level: 2

Workshop or Living Room aesthetic: Living room

Machine or Toy: Toy

Worth it? Depends how cheap you find it and what you want to print. For me? No.

|